CT Series is High pressure body with main body withstand pressure of 30 kP. It can be used in a high pressure dust/powder collection system of up to 30 kPa, which can not be used with an ordinary dust collector. It is active in high pressure applications such as long distance collection, central cleaning, product recovery. (Can accommodate up to 56.9 kPa for custom order)

High-pressure, medium airflow dust collector

- Used for pneumatic conveyance and central cleaning.

- High-pressure design (up to 30 kPa).

- Can be used for long distance dust collection, central cleaning and particle recover

Woven filter

Various filter are available

Material: Polyester

Surface treatment: Singed

Corresponding models: WRT, BV and CT

Application: General dried particles (particle diameter about 10μm)

Features

- General dried particles (particle diameter about 10μm)

- Standard filter. The most widely used item.

- Collecting efficiency: Good

- Heat resistant temperature (F): Normal temperature 120˚C (248˚)

- Acid-resistant: Average

- Alkali-proof: Average

It can also be used for dust collection at high temperature exhaust gas (210 ° C) with air volume of 75 m 3 / min. Since there are plenty of filter types, you can choose the optimum filter according to the application.

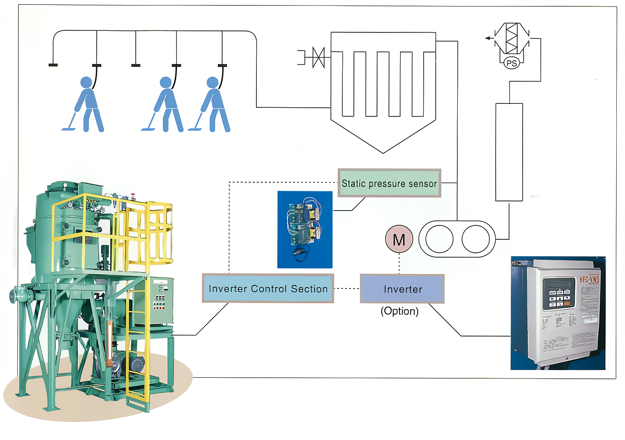

CT Series Central Cleaning System Sample Layout

Maximum Vacuum Power with Minimum Energy Consumption

There is no need to worry about vacuum power loss even when many inlet ports are in use. When the system is operating, the inverter(Option) control circuitry adjusts the blower motor r.p.m. accordingly to maintain constant vacuum power. Even with many inlet ports in use at the same time, a constant sustained vacuum power makes highly efficient and concentrated cleaning possible with minimal energy consumption.

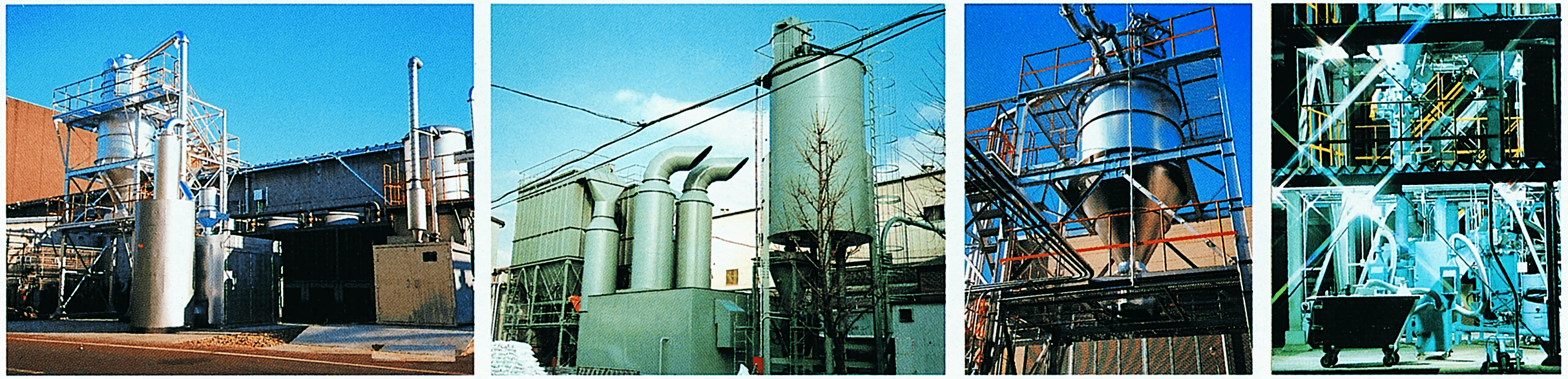

CT Series Sample Installation of Metal cutting ship automatic collection system

CT Series Sample Syetm Flow of Metal cutting ship automatic collection system

External View

Units: mm

Sample Installation

SPECIFICATIONS

| Model | Type | Dimension | (Unit:mm) | Filter Area | No of Filter | Weight | |||

|---|---|---|---|---|---|---|---|---|---|

| D | H | M | L | m2 | pcs | kg | |||

| CT-1008 | 1 | 765 | 3390 | 1065 | 1515 | 3.6 | 8 | 255 | |

| -2008 | 1 | 765 | 3990 | 1065 | 1515 | 5.8 | 8 | 315 | |

| -2014 | 1 | 950 | 4220 | 1250 | 1700 | 10.2 | 14 | 385 | |

| -2018 | 1 | 1100 | 4400 | 1400 | 1850 | 13.1 | 18 | 470 | |

| -2024 | 1 | 1250 | 4580 | 1550 | 2000 | 17.4 | 24 | 570 | |

| -4008 | 1 | 765 | 4690 | 1065 | 1515 | 8.4 | 8 | 370 | |

| -4014 | 1 | 950 | 4920 | 1250 | 1700 | 14.7 | 14 | 460 | |

| -4018 | 1 | 1100 | 5100 | 1400 | 1850 | 18.9 | 18 | 565 | |

| -4024 | 1 | 1250 | 5280 | 1550 | 2000 | 25.2 | 24 | 680 |

| Model | Type | Dimension | (Unit:mm) | Filter Area | No of Filter | Weight | |||

|---|---|---|---|---|---|---|---|---|---|

| D | H | M | L | m2 | pcs | kg | |||

| CT-2030 | 2 | 1400 | 4760 | 1700 | 2600 | 21.8 | 30 | 720 | |

| -2038 | 2 | 1525 | 4930 | 1825 | 2725 | 27.6 | 38 | 820 | |

| -2046 | 2 | 1700 | 5100 | 2000 | 2900 | 33.4 | 46 | 930 | |

| -2054 | 2 | 1900 | 5330 | 2200 | 3100 | 39.2 | 54 | 1090 | |

| -2064 | 2 | 2000 | 5460 | 2300 | 3200 | 46.5 | 64 | 1535 | |

| -2074 | 2 | 2150 | 5590 | 2450 | 3350 | 53.7 | 74 | 1705 | |

| -2086 | 2 | 2300 | 5750 | 2600 | 3500 | 62.4 | 86 | 1945 | |

| -4030 | 2 | 1400 | 5460 | 1700 | 2600 | 31.6 | 30 | 805 | |

| -4038 | 2 | 1525 | 5630 | 1825 | 2750 | 40 | 38 | 985 | |

| -4046 | 2 | 1700 | 5800 | 2000 | 2900 | 48.4 | 46 | 1110 | |

| -4054 | 2 | 1900 | 6030 | 2200 | 3100 | 56.8 | 54 | 1270 | |

| -4064 | 2 | 2000 | 6160 | 2300 | 3200 | 67.4 | 64 | 1790 | |

| -4074 | 2 | 2150 | 6290 | 2450 | 3350 | 77.8 | 74 | 1980 | |

| -4086 | 2 | 2300 | 6450 | 2600 | 3500 | 90.5 | 86 | 2250 |